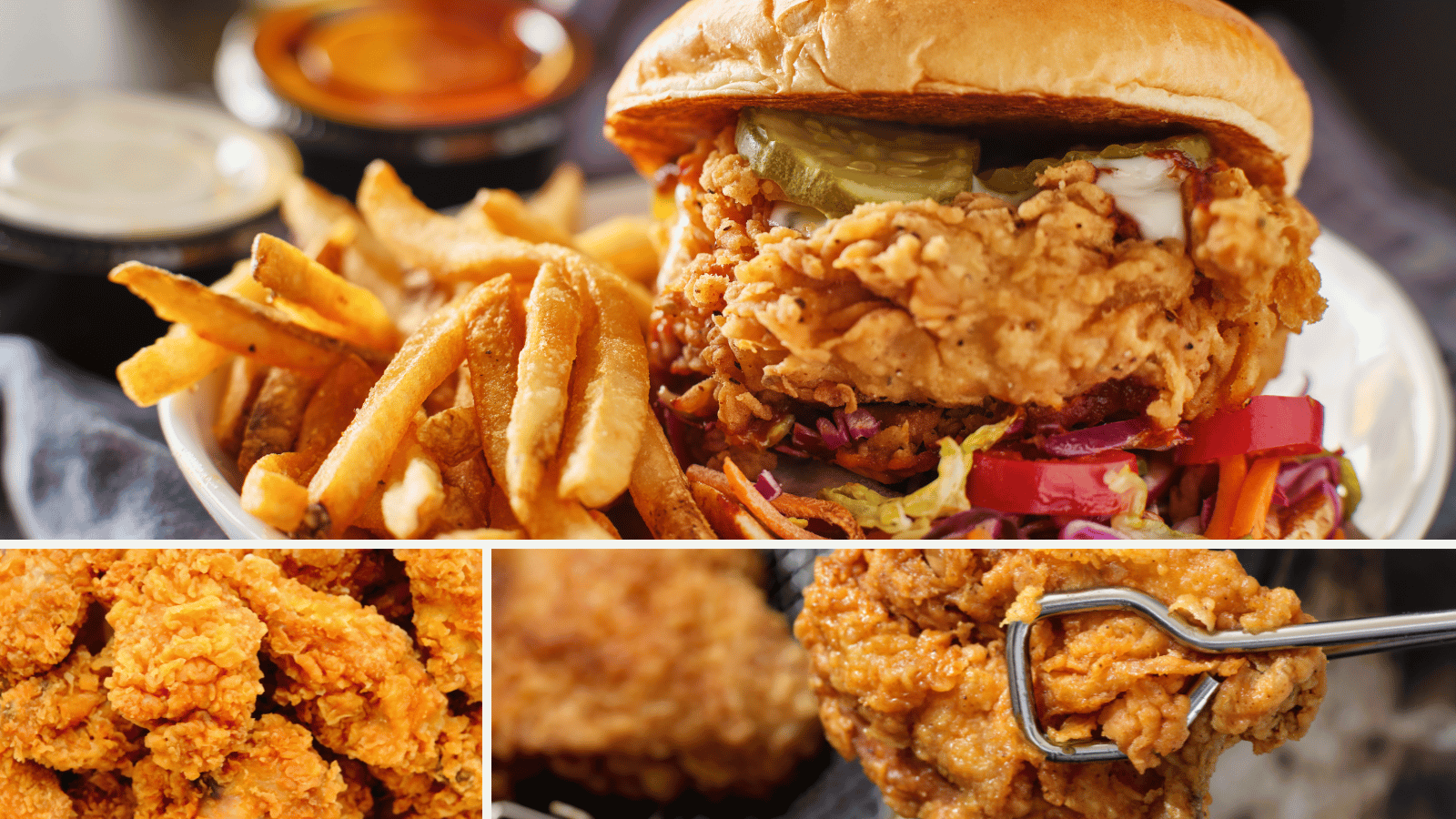

Why Fried Chicken Kitchens Break Down During Peak Hours

Peak hours expose everything that usually stays hidden. A commercial kitchen serving fried chicken can feel under control during slower periods, but it can unravel quickly once the lunch or dinner rush hits. Orders stack up, ticket times stretch, quality starts to wobble, and the kitchen shifts from controlled to chaotic in a matter of minutes. For many operators, this moment feels like a staffing issue or a training gap. More often, it is a system problem showing itself under pressure.

Busy Is Not the Same as Overloaded

Fried chicken operations rely on balance. Frying, holding, breading, and recovery all occur in parallel, each with its own limitations. During steady volume, those limits stay aligned. Peak hours change the conditions entirely. Instead of responding to individual orders, the kitchen absorbs sustained demand across all stations simultaneously.

This is where many peak-hour restaurant problems begin. The operation continues to move forward, but it loses margin. When one part of the system slows, everything behind it follows. What feels like a sudden breakdown is often a slow buildup that reaches its limit.

When Fryer Capacity Sets the Pace

Commercial fryer capacity becomes a constraint as soon as the baskets are full, and production reaches its maximum. Once that happens, kitchens lose flexibility. There is no buffer to absorb spikes in orders without delaying drops or disrupting flow.

As volume increases, staff are forced into constant tradeoffs. They hold product longer than planned or stagger batches and accept longer ticket times. Both decisions introduce inconsistency. The fryer becomes the pacing factor for the entire line, and the rest of the kitchen waits on it.

Recovery, Consistency, and the Compounding Effect of Peak Volume

Recovery time becomes the hidden constraint during peak service. As baskets cycle back-to-back, oil loses heat faster than some systems can rebuild it. Temperature dips compound across consecutive drops, stretching cook times and making batch timing harder to predict when volume is highest. Early orders move smoothly, then performance starts to slip. Staff adjust on the fly to keep orders moving, adding mental strain and increasing variability. The kitchen stops executing a process and starts reacting to conditions.

Peak periods rarely rely on a single cook or station. Multiple team members rotate through the fryer as volume stays high. When systems demand constant manual adjustment, even experienced crews struggle to stay aligned. Slight differences in timing or handling become more apparent under pressure. Product quality varies from batch to batch, communication becomes tighter, and tension builds between stations as they try to keep pace. The system does not reinforce consistency. It amplifies stress.

Oil Breakdown Raises the Stakes During the Rush

Oil degradation quietly compounds peak-hour challenges. High-volume chicken production places continuous strain on oil, especially when drops are frequent and recovery is inconsistent. As oil breaks down, maintaining quality becomes increasingly challenging, and the need for more frequent filtering increases.

When commercial kitchens serving fried chicken struggle during peak hours, the problem is rarely the recipe or the crew. It is a system that cannot keep up with volume, recovery demands, or oil stress under pressure.

Research on improving kitchen speed suggests that system constraints, rather than staff performance, are the primary cause of service slowdowns during periods of high volume. When oil quality deteriorates during a rush, kitchens face an impossible choice: either push through and accept declining results or stop production to intervene.

Why Peak-Hour Breakdowns Are So Often Misdiagnosed

When service slips, teams naturally look at execution. Staffing levels, training, and effort are subject to scrutiny. When experienced crews struggle only during peak hours, the pattern points elsewhere.

If the kitchen cannot maintain a consistent temperature, support accurate batch timing, or protect oil integrity under sustained load, performance will falter regardless of skill or effort. The issue is not the team. It is the system reaching its limits.

The demand for fried chicken has become more complex as menus expand and service windows become tighter. One reason for the high demand is the evolution of fried chicken, from the rise of the chicken sandwich to the push for all-day offerings like chicken and waffles, which reflects why modern kitchens face heavier peak-hour pressure than ever before.

Recognizing that pressure is the first step toward regaining control. Kitchens that stay composed during rushes do not rely on heroics. They rely on systems designed to perform during the busiest times of the day.