Commercial Kitchen Tech Upgrades to Plan Now

The walk-in cooler alarm goes off at 2 a.m. A combi oven throws an error code mid-rush. The fryer oil hasn’t been changed in a week because nobody remembered. These aren’t isolated incidents. It can often be the standard Saturday night.

For operators juggling labor instability, rising costs, and food safety pressure, making the right commercial foodservice equipment selections can be critical. Another important consideration is the increasing capabilities of commercial kitchen technologies.

What Are the Most Important Commercial Kitchen Technology Upgrades?

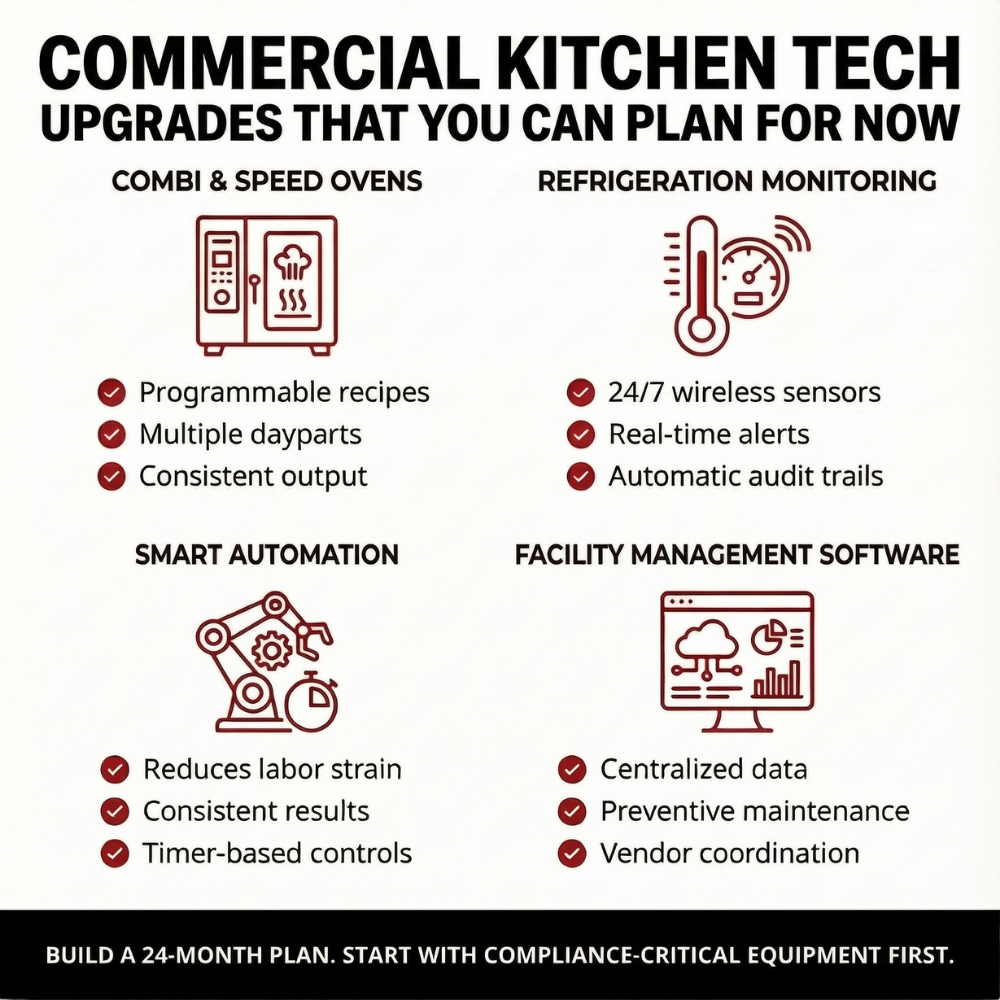

The most impactful upgrades focus on four areas: combi and speed ovens with programmable controls, refrigeration monitoring systems with wireless sensors, automation that reduces labor strain, and facility management software that centralizes equipment data.

Combi and speed ovens combine multiple cooking methods in a single unit, handling several dayparts while producing consistent results regardless of who’s on the line. Modern combis feature programmable recipes, automated cleaning cycles, and remote diagnostics. Combi demand continues to grow, driven by menu agility, higher yield on proteins, and labor relief.

Refrigeration monitoring prevents costly spoilage and creates automatic audit trails for health inspections. This is important considering how refrigeration failures are among the most expensive surprises in foodservice. Wireless sensors track walk-ins, reach-ins, and prep tables around the clock—when temperatures drift, you get alerts instead of spoiled inventory.

Automation addresses labor shortages and the need for consistent output. Think automated fryers that lift baskets on a timer, dishwashers that adjust cycles based on load size, and conveyor ovens that maintain exact temperatures without manual intervention.

Facility management software makes equipment data actionable—tracking performance, scheduling preventive maintenance, and consolidating repair history. Your facility management software should be easy to use from the day it’s implemented for everyone at the restaurant, regardless of how long they’ve been there.

How Should Operators Prioritize These Upgrades?

Start by mapping your pain points. Which equipment fails most often? Where do you lose the most labor hours? What keeps you up at night during health inspections? Then build a 24-month plan. Compliance-critical equipment, such as refrigeration, should be prioritized first. Labor and uptime investments follow. Menu agility upgrades—combis, speed ovens, modular gear—round out the list. The goal isn’t to chase every trend. It’s to make decisions now that prevent emergencies later.

Frequently Asked Questions About Commercial Kitchen Tech

What is the most important kitchen technology upgrade right now?

Refrigeration monitoring. Temperature drift and equipment failure can destroy inventory overnight, and wireless sensors with real-time alerts prevent spoilage while creating automatic audit trails for inspections.

Can small restaurants benefit from kitchen automation?

Yes. Small operations often benefit most from targeted automation because they have less margin for error. Automated fryers, programmable ovens, and timer-based equipment reduce reliance on experienced staff and improve consistency.

What should I look for in facility management software?

Choose software designed for foodservice—not generic platforms built for other industries. Look for mobile-friendly interfaces, vendor coordination, preventive maintenance scheduling, and 24/7/365 support from real humans with restaurant industry experience.

Do connected kitchen devices create cybersecurity risks?

Yes. For big-ticket pieces, ask about data exports, remote diagnostics, and security posture. Segment IoT devices on a separate network from POS and payment systems.